![]()

VICON MACHINERY

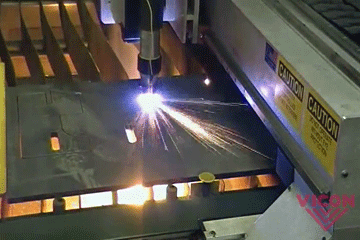

PRECISION PLASMA BURNING TABLES

VICON Precision Cutting Torches

When choosing a precision cutting system, there are many factors that need to be considered – part application, type and thickness of material to be cut, cut quality, system cost, and overall operating expense. In addition, there are a variety of precision systems available to the market today – ranging from manual gas consoles to automatic gas consoles, and units capable of cutting light gauge to heavy plate.

The Vicon Precision Cutting Toches can be custom designed for cutting based on your shop criteria as mentioned above. Our highly trained VICON sales and technical specialists will eliminate the guesswork and engineer a system utilizing the “right” torch that will enable you to achieve the goals you are looking to accomplish through plasma technology. Through sample parts and time studies, you can see the end results before making a final decision.

At Plasma Automation, we incorporate only systems manufactured by industry leaders in plasma cutting technology. System warranty and service are impeccable and expert advice is always available through developed partnerships with leading torch manufacturers.

Electronic Torch Height Control and Collision Protection

To enhance the efficiency of each torch system, the VICON cutting torchesincorporate your choice of electronic torch height control, which maintains a precise cutting height of the torch during the piercing and cutting cycles to further enhance cut quality. A collision protection device is also added to protect your torch investment from damage in the event of collision with the material.

Machine Electronics and Motion Controller

The solid-state controls and digital drives ensure fast response time and precise motion during the cutting process while the solid-state non-contact proximity sensors protect the drive train while producing your parts at the highest rate possible. Communications from the PC controller to the digital servo drives are through fiber-optic signaling cables to ensure reliability within the system

ViSoft Cutting Software Program for Windows

The ViSoft software is menu-driven and user-friendly. Written and supported by Plasma Automation’s experienced team of in-house programming engineers, we are consistently enhancing and updating the Vicon program to continue to bring users the latest and greatest in functionality. Features include a full array of shapes with user-defined libraries, Super Nest and common line cutting for the ultimate in material utilization, time saving DXF file importing including Auto Kerf and Auto Lead-In, and a true CAD sketch program…to name a few.

VICON Monarch Plasma Cutting Table

Heavy Duty Precision Plasma Cutting System

![]() The Ultimate in Heavy Duty Precision Performance

The Ultimate in Heavy Duty Precision Performance

The Vicon Monarch CNC plasma cutting machine is an extremely rigid, accurate and versatile system. The dual precision worm gear drives with digital motors produce precise movement of the all aluminum tubular gantry. This, coupled with its sharp crisp motion, produces the most accurate parts that a plasma system can possibly provide. The end result is a high quality part with superb edge quality.

When it comes to heavy-duty, high-end precision cutting systems, no other solution brings more to the table than the VICON Monarch, high-precision plasma cutting machine with fierce I-beam construction. The only feature more impressive than its accuracy is the incredible versatility of its options. Precision sheet metal, thick plate, structural steel, I-beam, angle iron, channel, tubing and fixturing type cutting are some of the flexible capabilities that the Monarch delivers.

VICON Elite Plasma Cutting Table

High Precision Plasma Cutting System

![]() Performance Has Never Been More Precise

Performance Has Never Been More Precise

The Elite is an extremely rigid, accurate and versatile plasma cutting system. The dual precision worm gear drives with digital motors produce precise movement of the all aluminum tubular gantry. This, coupled with its sharp crisp motion, produces the most accurate parts that a plasma system can possibly provide. The end result is a high quality part with superb edge quality.

The gantry can accommodate multiple stations such as plasma torches, oxy torches, scribing tools and drill heads. Built in material stops, clean out doors and a machine status panel are just a few of the well thought out machine features that provide trouble free operation and optimum performance for years to come.

VICON Fabricator Plasma Cutting Table

Plasma Cutting System

![]()

The Solution for Fabrication and Job Shop Applications

The VICON Fabricator is a rugged yet flexible plasma cutting machine. It is the solution for the optimal processing of fabrication or job shop applications. Fast, clean and accurate, this CNC cutting system drastically reduces waste and operating costs resulting in greater profitability.

Contact us for more information:

Or give us a call at: 303-466-7341

Monday - Friday, 7:00 AM - 5:00 PM, MST