![]()

BERTSCH SHEET AND PLATE ROLLS

Bertsch bending rolls are designed and built to accurately form metal from gauge thickness through 14" thick and larger, and can be custom designed to meet specific applications.

KEY ADVANTAGES OF BERTSCH PLATE ROLLS

More Pre-Bend

Bertsch machines pre-bend to the machine’s rolling capacity. Most competitors specify less pre-bending capacity than rolling capacity.

Minimum Rolling Diameter at Maximum Material Thickness/Width

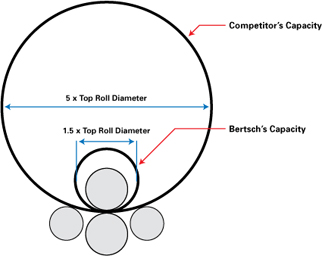

Bertsch rates its machines to pre-bend and roll material to small diameters. Most competitors limit their maximum capacity to five times the top roll diameter.

Designed for Longer Life

Rectilinear guides provide longer service life and maintain better parallelism over the life of the machine.

Better Quality Parts

Rectilinear guides also produce the smallest flats on the ends of rolled parts.

Easier to Use

Bertsch’s electronic leveling system allows operators to make roll corrections on both ends of each roll, not just one end.

Higher Capacity

Bertsch rates its machines for the nominal thickness and length of the machine. For example, a 1-inch, 10-foot machine can roll a 10-foot wide piece of 1-inch thick material to its minimum roll diameter. Other manufacturer’s specifications are more closely matched to Bertsch’s smaller capacity models.

Comparison of 1 in./10 ft. Rolls — Pre-Bending

While many manufacturers have the ability to roll to their maximum capacity, they cannot pre-bend the material. This forces the user to either pre-bend material on a press brake, or purchase a larger machine with higher capacity.

Comparison of 1 in./10 ft. Rolls

Rolling Capacity – 146” Diameter

Comparison of 1 in./10 ft. Rolls

Rolling Capacity – 16.8” Diameter

Contact us for more information:

Or give us a call at: 303-466-7341

Monday - Friday, 7:00 AM - 5:00 PM, MST