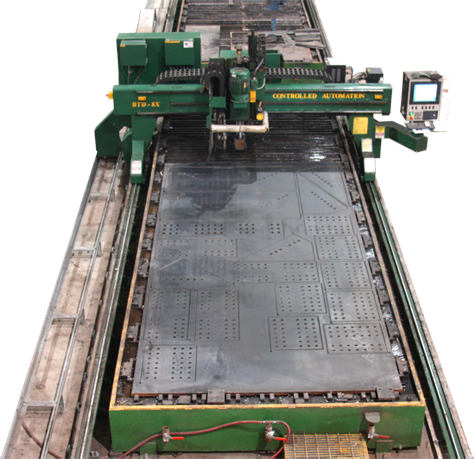

The BTD-8X is Controlled Automation's entry level drill-and-burn plate processing machine. Each machine comes standard with an 8' working width and and a lenth of up to 124'. Drilling operations are performed using a 10 HP spindle with Controlled Automation's own proven drilling technology. A high definition plasma torch cuts material up to 2 ½ " thick and a standard automated oxy-fuel torch cuts material up to 4" thick.

Features:

The BTD-8x includes all of the standard features listed above.

BTD-8X Specifications:- Max drill size: 1-9/16"

- Spindle Type: #4 morse taper

- Machine advance speed up to 845"/min

- Positioning accuracy:

+/- .007" (single axis only)

+/- .015" (coordinate axis) - Horsepower: 10 HP variable AC standard

- Variable spindle RPM: 300-1200 RPM

- Plasma system: Hypertherm HPR260xd

- Oxy-fuel system: 4" Automatic gas

-

Machine:

- Maximum processing width: 8' Drill Spindle

- Maximum hole diameter: 1-9/16"

- Minimum material thickness: 1/4"

- Max. material thickness: 2-1/2" (production) Plasma Torch

- Max. edge start (pierce pilot hole): 2-1/2" (as per oem spec)

- Maximum pierce: 1-1/2" Oxy-fuel torch:

- Maximum material thickness: 4"

Description:

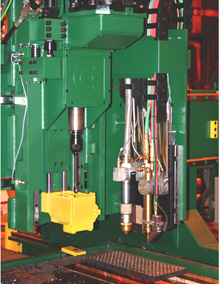

The Gantry Plate Drill gives fabricators high performance drilling in the largest work envelope with widths up to 144 inches. The GPD-144 has the rigidity and precision normally found only in high-end machining centers. Complemented with a powerful ram style headstock and coolant through the spindle, this drill achieves high metal removal rates for maximum productivity. The user-friendly SICAM Windows control system is packed with features to help make quick work of even the largest

drilling jobs.

Standard Features:

Each Controlled Automation drill-and-burn plate processing machine features the highest quality construction and specifications:

- Carbide drilling with through-spindle mist or flood coolant.

- Dual-side independent rail axis drive package.

- Air conditioned Windows 7 controller.

- Processing parameters for drill, plasma and oxy-fuel operations set automatically.

- Rigidly constructed tubular steel gantry

- Dual side independent rail axis drive package

- Crash detection on both plasma & oxy-fuel systems

- Automatic torch height control system

- Automatic oxy-fuel gas control system

- Automatic torch ignition system

- Processing parameters for drill, plasma, and oxy-fuel operations set automatically

- Managable hole properties database

- Standard auto-nesting package

- Easily networked

- Fully automated tool changer

- Max Drill Size: 3 ½"

- Plasma: Hypertherm HPR 400xd

- Oxy-Fuel: 6" automatic gas

- Horsepower: 30 HP variable AC standard

- Spindle RPM ranging from 0 - 2400 variable

- Spindle Type: CAT 50

- Face/surface milling

- Maximum processing width: 6' to 8'

- Maximum processing length: 4' to 30' Plasma Torch

- Maximum material thickness: 1-1/4" (piercing start)

- Minimum material thickness: 20 gauge Oxy-fuel Torch

- Maximum material thickness: 4"

Description:

Maximize your 10' plate production needs with Controlled Automation's new GPF-10X gantry-style plate fabricator. This machine is capable of drilling holes up to 2-1/4" diameter and cutting steel plate up to 6" in thickness. The system includes a fully automated 10 position tool changer, 20 hp CAT 40 drill spindle, 400 AMP high definition plasma cutting and marking system with automated gas control, oxy-fuel torch cutting system with automated gas control, and SICAM® software to compliment Controlled Automation's advancements in technology.

GPF-10x Features:

All of the standard features listed above plus:

- 10 Position Fully Automated Tool Changer (optional)

- High performance carbide, spade, or twist bit drilling

- 20 hp variable speed spindles

- 100-1,200 variable spindle rpm

- Machine advance speed up to 845"/min

- Material positioning accuracy:

- +/-.007" (single axis only)

- +/-.015" (coordinate axis)

- Brushless AC servo / ball screw drill feed system

- Dual-side independent rail axis drive package

- Machine advance speed up to 600"/min

- Positioning accuracy +/- 1/32"

- Thru-spindle air-mist coolant system

- CAT 40 Spindle Taper

- Laser pointer to skew hole patterns & find start location

- HPR 400XD High Definition Plasma System

- #4 morse taper

- Max. Material Width: 10'

- Max. Material Thickness: 6"

- Max. Drillable Hole Size: 2-1/4"

- Max. Thrust: 4,200 lbs

Contact us for more information:

Or give us a call at: 303-466-7341

Monday - Friday, 7:00 AM - 5:00 PM, MST